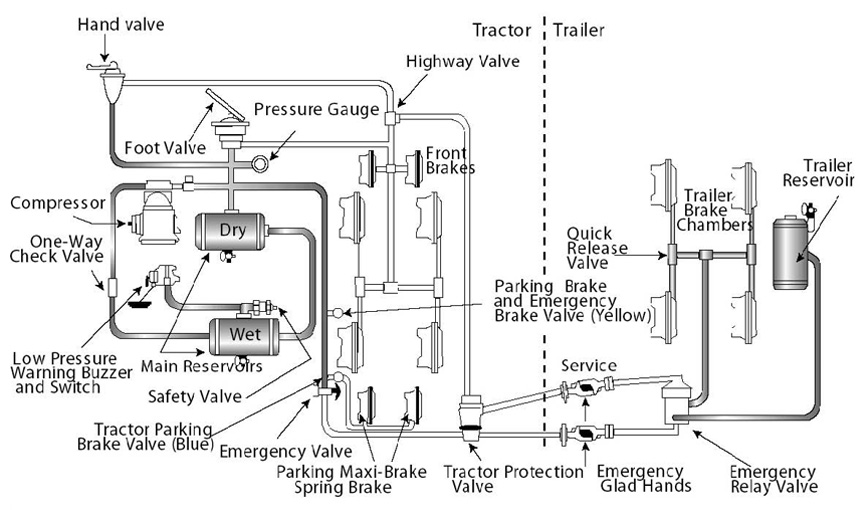

Air brakes (found on large trucks and passenger buses) are composed of an air compressor unit, air lines, and air brake chambers (aka “pots”). The air chambers – which act as a fail-safe in case the system loses pressure (typically below 60 psi) – are especially vulnerable to wear-and-tear over time.

Small air leaks in these systems are difficult to find. These leaks can quickly turn into big problems and add to operating expenses. For instance, when air break leaks occur, a vehicle loses adequate continuous air pressure. This causes the brakes to set and lock if the pressure gets too low. A truck in need of repair can cost a company upwards of $900 to $3,000 per day due to downtime and unproductivity.

Under certain driving circumstances, the air in brake systems can deplete quicker. For instance, air brakes are used less frequently on highways and are used rapidly in high-traffic or city driving. In these situations, it is vital for air brake systems to be fully pressurized. Companies can be liable if there is a traffic accident and lapses in the inspection and maintenance of parts.

The TP-9367 Marksman™ II Ultrasonic Diagnostic Tool can help make finding air brake leaks much less challenging. The Marksman II™ operates on the principle that pressurized leaks produce friction and ultrasonic sound at the leak site. The Marksman II™ converts and amplifies inaudible ultrasonic sound into an audible “natural” sound the ear can easily pick up. The result is quicker and extremely accurate air brake leak detection.