Europe’s automotive aftermarket is being shaped by two big regulatory forces

-

- F-gas rules that keep tightening around fluorinated refrigerants and emissions prevention

-

- REACH expectations that raise the bar on chemical transparency, risk management, and documentation

If you service A/C systems (and honestly, any vehicle fluid system), the simplest path to fewer headaches is the same: find leaks earlier, fix them once, and document the proof. That’s exactly where Tracerproducts Automotive and Tracer® UV dye + UV lighting fit as a preventative maintenance toolset.

1) F-gas in Europe: what’s changing and why it matters in automotive

The “new” EU F-gas Regulation (EU) 2024/573 raises the ambition

The EU updated its core F-gas law in Regulation (EU) 2024/573, which repeals Regulation (EU) No 517/2014 and strengthens the long-term push to reduce F-gas emissions and accelerate the transition toward lower-GWP alternatives.

What that means for service and maintenance teams:

-

Leaks are no longer just a “comeback” problem—they’re an emissions and operational risk problem.

-

Refrigerant governance is getting stricter across the value chain (equipment handling, recovery practices, and market controls), and the overall direction is continued tightening—not loosening.

Mobile A/C has its own rulebook: the MAC Directive

Separately from the general F-gas framework, the EU’s MAC Directive (2006/40/EC) requires the use of refrigerants with GWP < 150 in mobile A/C systems for passenger cars and certain light commercial vehicles—driving the shift away from R-134a in new vehicles.

Why this matters in the bay:

-

You’re servicing a mixed fleet—older R-134a vehicles and newer low-GWP platforms—so accuracy and speed matter more than ever.

-

Preventing “top-off culture” (repeated recharge without root-cause repair) becomes a bigger business risk as refrigerant and service expectations tighten.

Technician qualification: recovery work requires training/attestation

For recovery of F-gases from vehicle A/C systems, the EU set minimum training requirements under Commission Regulation (EC) No 307/2008, including mutual recognition of training attestations.

2) REACH: not a single “certification”—a system of responsibilities

REACH (Regulation (EC) No 1907/2006) is the EU’s foundational chemicals framework—covering registration, evaluation, authorisation, and restriction of substances. It places responsibility on companies to identify and manage risks associated with chemicals they manufacture or place on the EU market. EUR-Lex+1

The practical REACH pressure points for aftermarket products

Even if you’re “just” a distributor, importer, or service organization, REACH shows up in daily work through:

- Safety Data Sheets (SDS): REACH defines format/content and when an SDS must be provided. ECHA+1

- SVHC / Candidate List obligations: if a substance is on the Candidate List, specific communication duties apply across the supply chain. ECHA

- Documentation discipline: the expectation is traceability—what was used, how it was handled, and what information was provided to downstream users.

3) Other EU initiatives worth tracking (because they’ll hit supply chains)

Even if your day-to-day is vehicle service, these policies increasingly influence OEMs, Tier suppliers, and product requirements:

- Chemicals Strategy for Sustainability (EU): pushes “safe and sustainable by design” and supports the EU’s zero-pollution ambition—this direction influences restrictions, reporting, and substitution pressure over time.

- PFAS restriction work under REACH: ECHA is progressing a broad PFAS restriction proposal—important because it can affect materials, formulations, and some industrial product categories over time.

- End-of-Life Vehicles (ELV) policy refresh: the EU is actively updating ELV rules to improve dismantling/recycling and circularity—more documentation and materials scrutiny tends to follow.

4) Why preventative maintenance is the “compliance-friendly” strategy

If you boil it down, Europe’s direction is: reduce emissions, improve traceability, and tighten chemical governance.

Preventative maintenance helps because it:

- reduces refrigerant loss (emissions + cost)

- minimizes repeat handling of regulated refrigerants

- creates clearer documentation for customers and internal QA

- improves first-time fix rate, which is the operational win everyone feels

5) Where Tracerproducts Automotive fits: preventative leak detection you can prove

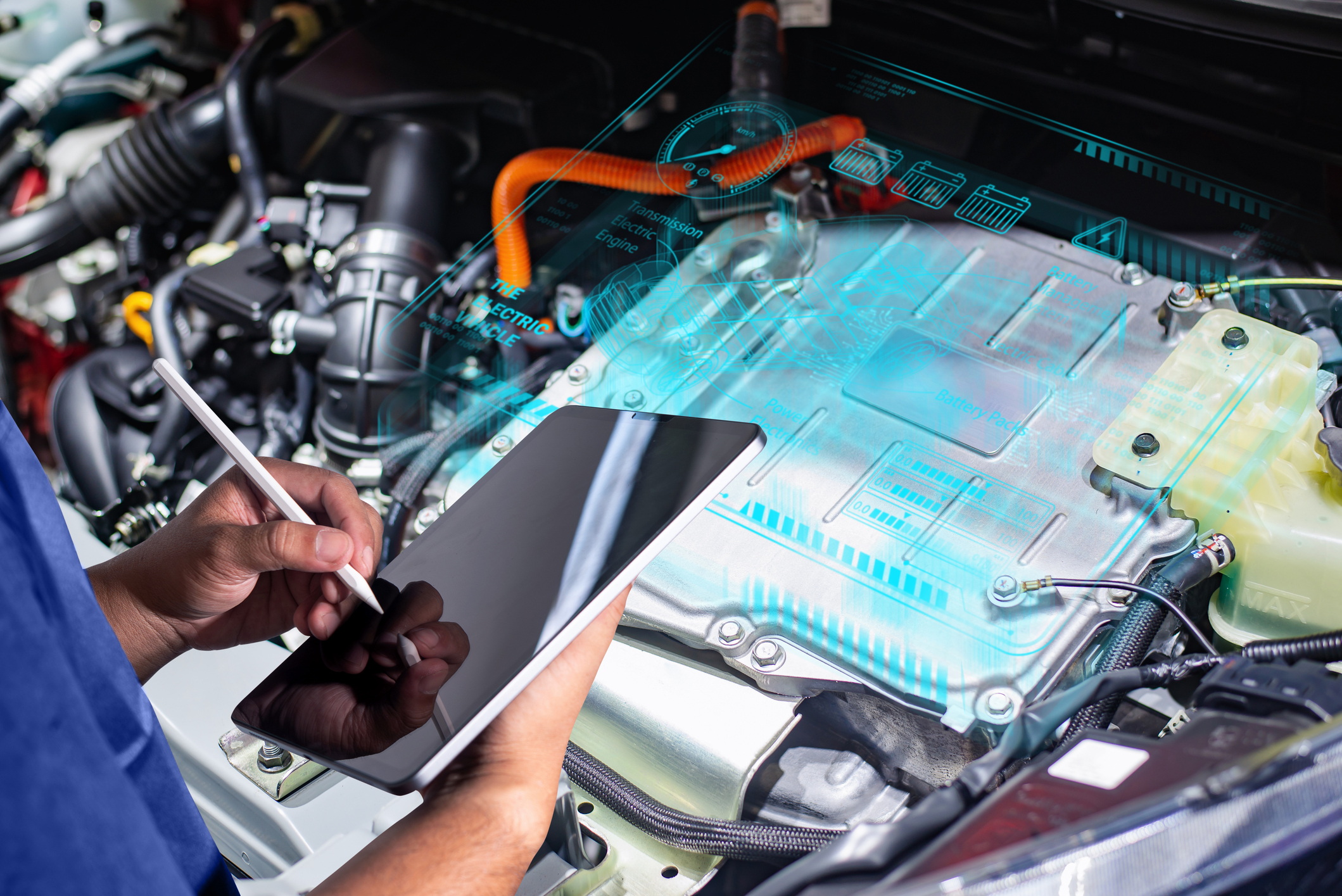

Tracerproducts’ UV dye + UV light workflow supports the exact behaviors regulators and OEM programs increasingly reward: find it early, fix it correctly, verify it visually.

A/C systems (R-1234yf and today’s platforms)

Tracerproducts offers A/C dye kits formulated for modern systems (including R-1234yf), designed to make small leaks visible quickly under UV inspection—ideal for proactive checks during service intervals.

Vehicle fluid leaks beyond A/C (oil, ATF, power steering, fuel, etc.)

For oil-based systems, Tracerproducts UV fluorescent dye is designed to pinpoint leaks across common vehicle fluids and can remain in-system for ongoing inspection—making it a natural fit for preventive maintenance programs.

Documentation and chemical communication (REACH reality)

You don’t want to scramble for documentation when a customer asks for it. Tracerproducts maintains an SDS repository, and example SDS files are readily available—supporting the kind of downstream communication REACH expects.

Important note (the safe way to say it): You can acknowledge European regulatory awareness and strong documentation practices without claiming blanket “compliance” for every jurisdiction/use case.

6) A simple “EU-ready” preventative maintenance workflow (shop-friendly)

Here’s a practical routine you can build into service packages:

- Baseline inspection (visual + customer symptom review)

- Add UV dye to the applicable system (A/C or fluid system) per product guidance

- Run/operate the system under normal conditions

- Scan with UV light across known leak points (connections, seals, compressor area, hose crimps, service ports, gaskets)

- Capture proof (photo + work order notes)

- Repair + re-scan to verify the fix before delivery

This turns leak detection from a reactive scramble into a repeatable, documentable process—exactly what preventative maintenance should be.

Closing: Regulation is pushing the market—preventative maintenance is how you stay ahead

Europe’s F-gas trajectory and REACH expectations both point to the same operational truth: leaks cost more than the repair. Tracerproducts Automotive gives shops a practical way to reduce emissions risk, cut diagnostic time, and create visual verification that supports customer trust and stronger records.

If you want, paste your current draft (or your preferred tone—technical vs. marketing-forward), and I’ll tailor it to your exact blog style, with a tighter Tracerproducts CTA and internal-link placeholders for your site.