Tracer Wafer for OEM applications embeds a compact, solvent‑free UV dye wafer inside the receiver‑drier’s desiccant bag so every A/C system leaves the line leak‑detection ready. When leak detection is built into the vehicle at the factory, service stops being a hunt and starts being a quick confirmation. The result is faster, repeatable diagnostics in the service bay, fewer retests, and tangible warranty savings—without adding steps or complexity to the assembly line.

Why OEMs choose Tracer Wafer

The core promise is simple: speed and certainty. With Tracer Wafer for OEM applications, technicians can pinpoint the true source of an A/C leak in about 15 minutes because the dye travels with the system oil and causes leak sites to fluoresce brightly under UV/blue light. What used to consume multiple billable hours becomes a quick, repeatable check that supports first‑time‑fix rates and lowers warranty exposure. By utilizing the Tracer Wafer, the average repair labor drops from roughly $450 to $37.50, translating to about $412 per vehicle in savings across millions of vehicles serviced.

The savings story is only part of the value. Service outcomes improve because the UV contrast makes small leaks easier to see, while engineering and quality teams benefit from tighter feedback loops—clear evidence of where defects present and how often. Together, these gains make Tracer Wafer for OEM applications a defensible standard for production programs and warranty programs alike.

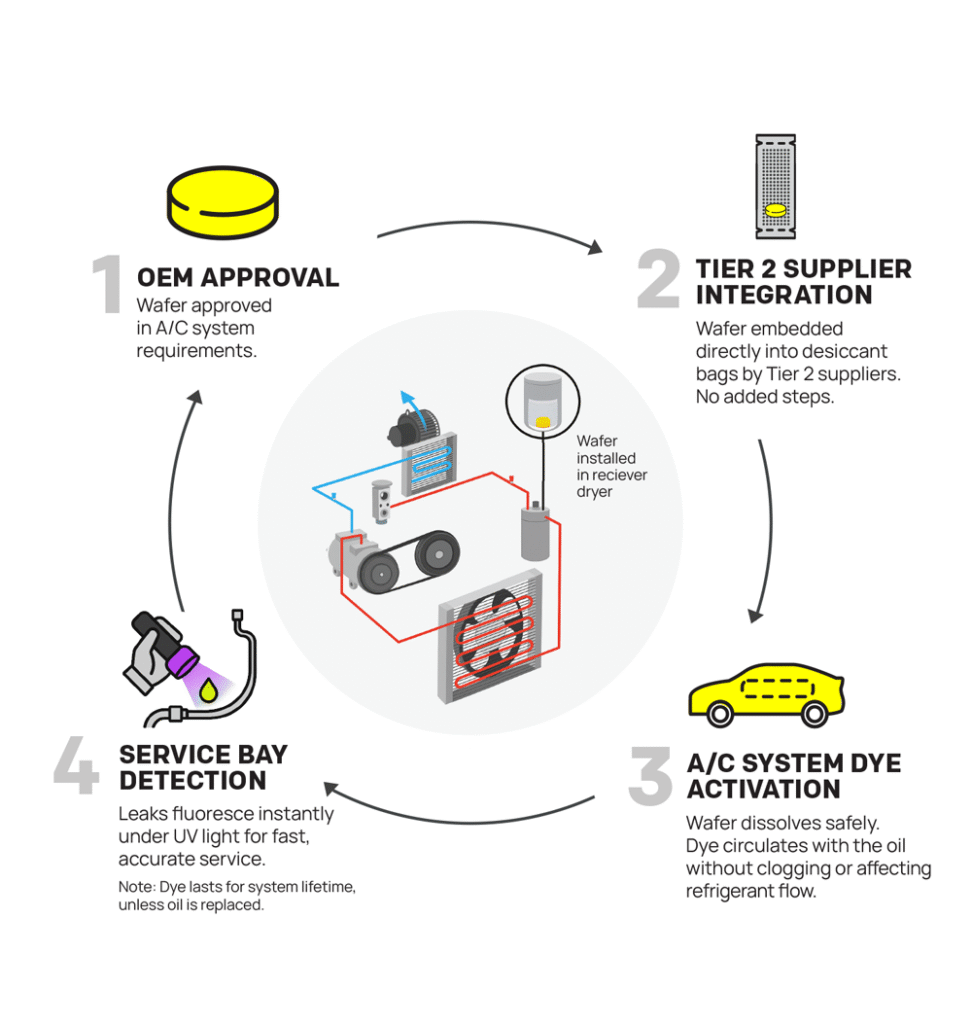

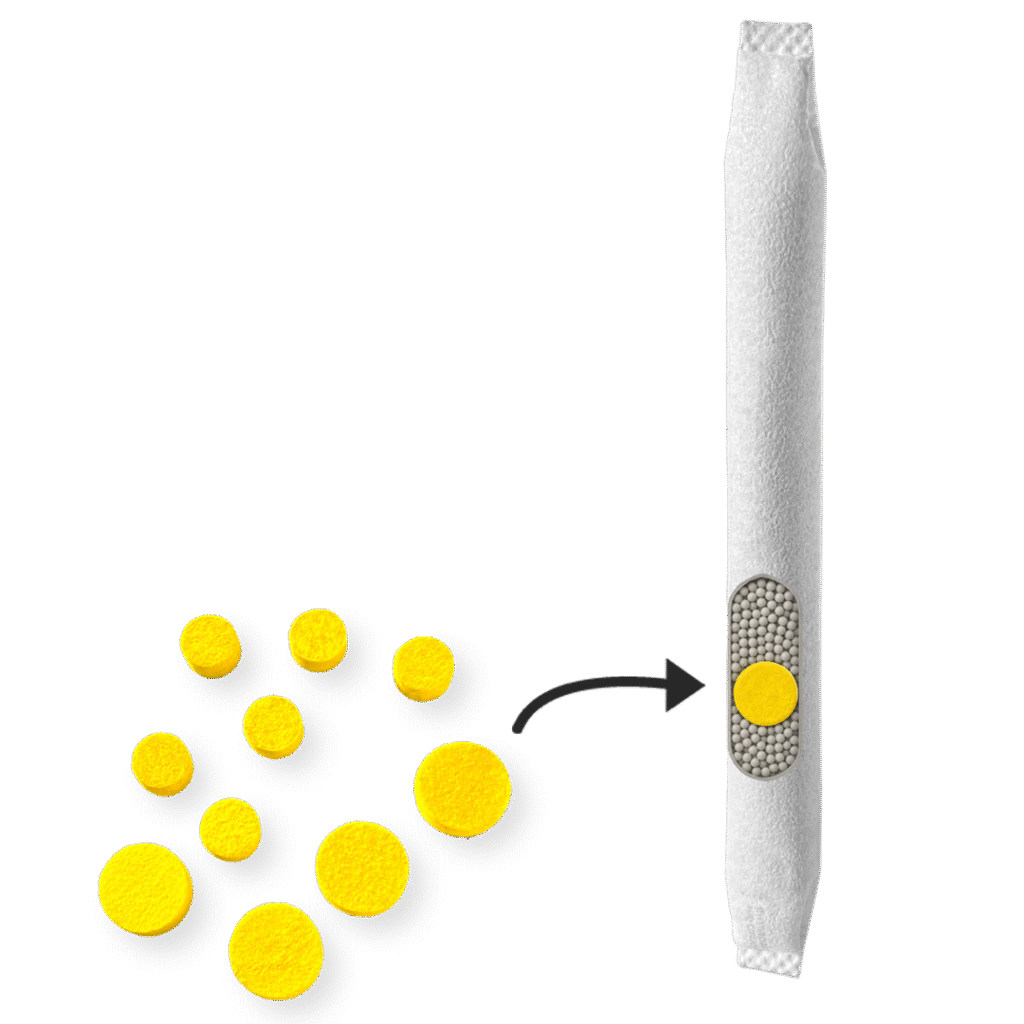

How it integrates—without changing the line

Integration is upstream and elegant. Tier‑2 partners embed the wafer inside the receiver‑drier’s desiccant bag, so the part arrives at your plant line‑ready. Your teams install the receiver‑drier as usual, with no added steps and no liquid handling. Once the vehicle runs, the wafer dissolves safely and the UV dye circulates with the oil for the life of the system—creating built‑in visibility anytime a technician scans with a UV/blue lamp.

Because the leak‑detection capability ships with the vehicle, there’s no dependency on dealer add‑ons, no inconsistent dye handling, and no extra workflow burden for the plant. It’s a production‑safe method to make diagnostics efficient, standardized, and repeatable across your platforms.

Proven brightness, proven results

Not all fluorescent dyes are created equal. The Tracer Wafer’s bright contrast equals faster repairs: leak points stand out immediately along fittings, hoses, and seals, allowing technicians to follow the trace to the true source and confirm the fix. Brightness is more than a visual—it’s a practical advantage that reduces repeat visits and retests.

In practice, Tracer Wafer for OEM applications is designed to deliver lifetime UV visibility under normal service conditions, so the diagnostic assist is always “on,” ready whenever a vehicle presents with A/C performance issues. That persistent visibility contributes directly to warranty cost control and customer satisfaction.

Compliance, compatibility, and safety

For engineering and quality teams, compliance and compatibility are non‑negotiable. Tracer Wafer for OEM applications is solvent‑free and SAE J2297‑aligned for refrigerant leak detection dyes—an essential assurance when standardizing across platforms. It is compatible with R‑1234yf and R‑134a, and supports ICE, hybrid, and EV A/C architectures, so you can apply a single, production‑safe method across evolving refrigerant strategies and vehicle portfolios. The Tracer Products’ ISO 9001:2015 certification is yet another signal of process discipline and quality management at scale.

Proof at scale: trusted by leading automakers

Adoption speaks louder than claims. Ford integrated the wafer in 1995, Nissan in 1999, GM in 2000, and Tesla in 2017—a lineage that demonstrates cross‑brand confidence in the technology. Today, the product is installed in hundreds of millions of vehicles worldwide, underscoring its reliability and repeatability in real‑world conditions. For OEMs evaluating risk, this depth of field use matters—few diagnostics aids can point to adoption breadth at this scale.

These programs reflect Tracer Products’ heritage: the company invented UV fluorescent leak detection and has been refining the approach for more than 70 years, delivering dyes, lamps, and tools that have become standard in service diagnostics. That lineage shows up in the wafer’s performance and the support ecosystem around it.

Benefits across the organization

Engineering & Quality: Built‑in UV visibility helps pinpoint manufacturing defects, validate assembly quality, and tighten root‑cause analysis. With Tracer Wafer for OEM applications, you have a standardized, production‑safe diagnostic assist that complements other QA methods and provides trace evidence under UV/blue light whenever it’s needed—on day one or years later.

Manufacturing & Operations: Because integration is at Tier‑2 and the receiver‑drier installs as usual, manufacturing sees no extra steps and no liquid handling. The approach is line‑neutral—ideal for plants focused on takt time, stability, and error proofing. It’s an incremental quality assurance layer that doesn’t consume process headroom.

Procurement & Supply Chain: You gain a drop‑in component with proven program history and broad compatibility. A single leak‑detection standard simplifies vendor alignment and reduces variability in service outcomes—benefits that show up in warranty cost metrics and customer satisfaction over time.

Service & Warranty: Faster, high‑confidence diagnosis (≈15 minutes) reduces retests and comebacks, improving first‑time‑fix rates and technician throughput. The warranty cost math—about $412 savings per vehicle on average, with labor falling from ~$450 to ~$37.50—illustrates how diagnostic efficiency converts into measurable dollars at fleet scale.

Sustainability & Refrigerant Stewardship: Catching small leaks early reduces wasted refrigerant, which carries both cost and environmental implications, especially with next‑generation refrigerants. Built‑in UV visibility encourages a preventive approach: find it, fix it, confirm it—quickly and consistently.

The bottom line

Tracer Wafer for OEM applications moves leak detection where it belongs: into production. By embedding a solvent‑free, SAE‑aligned UV dye wafer at Tier‑2 and shipping every vehicle leak‑detection ready, OEMs secure faster service, higher first‑time‑fix rates, and lower warranty cost—without touching the line. It’s proven at scale, compatible with current refrigerants and future‑leaning platforms, and supported by decades of engineering heritage in UV fluorescent diagnostics.