UV Leak Detection for Fleets: One Scan. Find Every Leak.

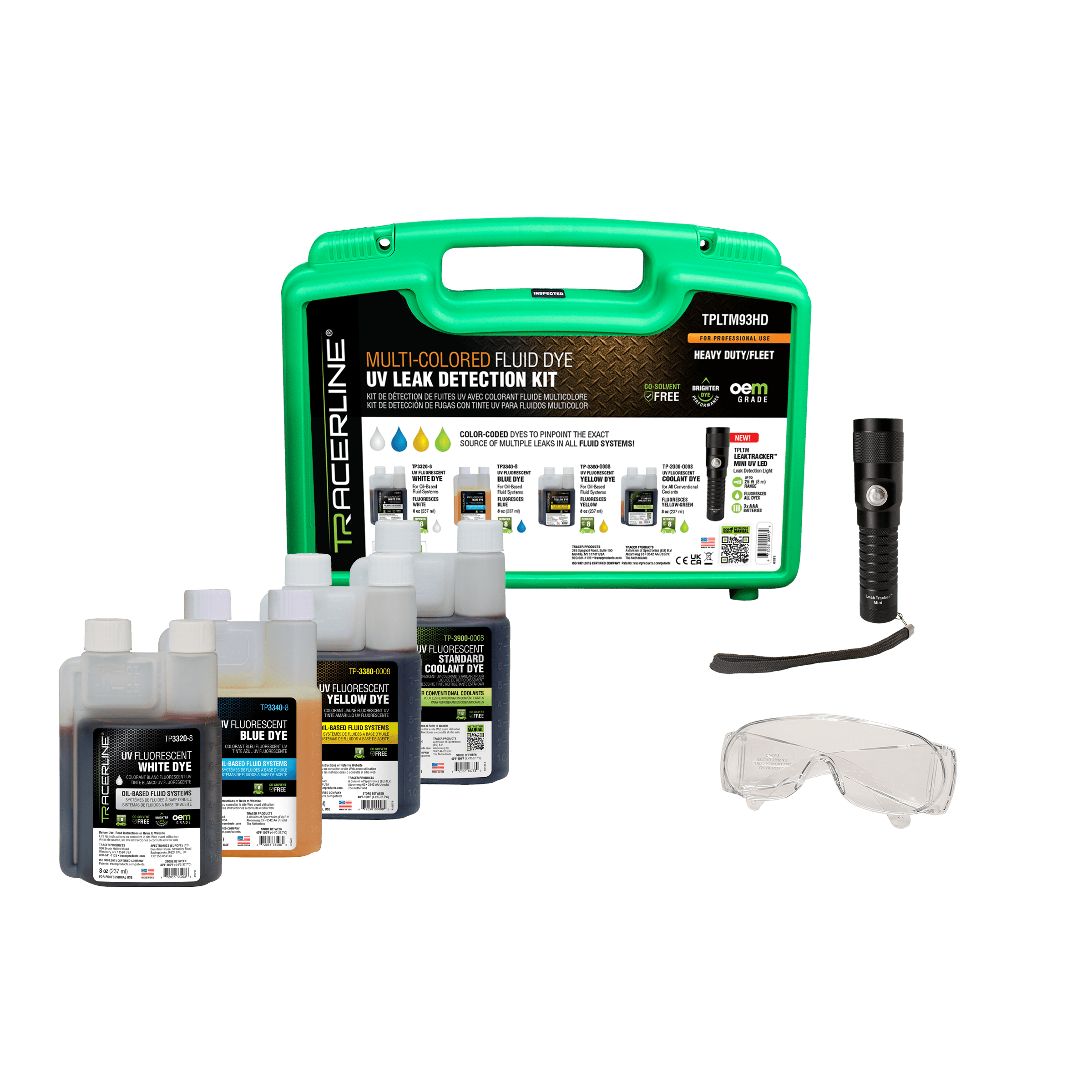

Keeping heavy-duty trucks and off-road equipment on the road is all about fast, confident diagnostics. Tracer Products’ TPLTM93HD Multi-Colored Fluid Dye UV Leak Detection Kit makes it simple: add color-coded dyes to systems once, run the vehicle, and scan with the included UV flashlight to spot leaks across multiple systems in a single inspection. That’s UV leak detection for fleets—done right.

Why Multi-Color Matters in UV Leak Detection for Fleets

Mixed leaks are common in high-hour vehicles. With Tracerline® multi-color dyes, each fluid tells its own story: white, blue, and yellow dyes tag petroleum and synthetic oil-based systems (engine oil, hydraulics, fuel, gear oil), while a dedicated green/yellow-green dye treats coolant. The result? You can isolate and confirm multiple leak sources at once—even in dirty diesel environments—without confusing one system for another. That clarity speeds repairs and cuts costly downtime.

What’s Inside the TPLTM93HD Kit

The TPLTM93HD is purpose-built for heavy-duty and fleet maintenance. It includes the LeakTracker™ MINI UV LED flashlight—engineered to fluoresce all specialty dye colors with a practical inspection range up to 25 ft—and the full set of color-coded fluid dyes for oil-based and coolant systems. Each bottle services multiple vehicles, and the full kit covers up to 32 vehicle systems, giving maintenance teams ample capacity for scheduled inspections or triage days.

Tracer Products designed this kit specifically for trucks, off-road equipment, and machinery where rugged, repeatable results are a must. Bright fluorescence helps techs pinpoint the exact source of leaks quickly—so parts get ordered faster and vehicles get back to work sooner.

Faster Inspections, Less Downtime

Here’s the workflow: dose the target systems with the appropriate dye, operate the vehicle to circulate, then scan once with the UV lamp. Leaks glow brightly at the precise failure point—fittings, hoses, seals, gaskets—so you can document, prioritize, and repair with confidence. It’s a proven method used by major automakers; Tracer Products’ OEM-grade fluorescent dyes are factory-installed by leading manufacturers worldwide, giving you assembly-line level quality in the service bay. That’s the performance edge of UV leak detection for fleets.

Bottom line: If your goal is to reduce diagnostic time, avoid repeat comebacks, and keep assets earning, the TPLTM93HD delivers clear, color-coded answers in one efficient scan.

Ready to see it in action? Explore the TPLTM93HD and equip your team with UV leak detection for fleets that finds every leak the first time. Contact Tracer Products to learn more or purchase.

Preventive Maintenance: Catch Leaks Early, Keep Assets Earning

Preventive maintenance isn’t just about changing filters on schedule—it’s about finding the small issues that become big breakdowns. With UV leak detection for fleets, you can make leak checks a standard PM task, not an emergency response. The TPLTM93HD’s multi-color dyes let techs tag each system once and scan a vehicle in a single pass, so you catch seepage at fittings, hose crimps, and seals before it costs you a tow, a missed delivery, or a customer.

A simple PM workflow that works:

-

Dose once during service. Add the appropriate dye to oil-based and coolant systems while the truck is already in the bay.

-

Run to circulate. Bring the system to operating temperature so dye reaches potential failure points.

-

Scan once with UV. Perform a fast top-to-bottom sweep—multi-color fluorescence makes cross-system leaks easy to separate.

-

Document and prioritize. Tag findings by color in your work order, capture quick photos, and schedule repairs.

-

Verify the fix. After repair, a follow-up UV check confirms the leak source is eliminated.

Why build UV checks into PM?

-

Fewer road calls and comebacks. Early detection stops drips from becoming downtime.

-

Better parts planning. You can order seals, hoses, and clamps proactively and batch repairs.

-

Cleaner bays and safer worksites. Leaks are messy, slippery, and non-compliant—find them before they spread.

-

Repeatable training. Color mapping simplifies onboarding for new techs and keeps inspections consistent across shifts.

Pro tip: Add a color legend to your PM checklist and label your dye bottles by system. Over time, your maintenance system will build a visual history of weak points—helping you refine service intervals and even move toward predictive scheduling. When every minute of uptime matters, folding the TPLTM93HD into preventive maintenance transforms inspections from guesswork into a quick, confident routine—and keeps your assets earning with UV leak detection for fleets built right into the plan.