EVs and hybrids are in the lane every day, and dealerships are need of EV/Hybrid UV Dye for efficient A/C diagnostics. The A/C concerns still read the same on the RO: weak cooling, intermittent performance, or “it was recharged recently.” In a dealership bay, the biggest drain isn’t only the leak, it’s the time lost to uncertainty. Rechecks, comebacks, and “maybe it’s this part” decisions slow throughput and create avoidable friction for advisors and customers.

A compatibility-first UV dye workflow helps by making refrigerant leaks visible. When the process is standardized, technicians can confirm leak location faster, verify repairs under UV, and leave consistent notes that support the recommendation.

Why EV/Hybrid A/C leak detection feels different in today’s service bays

The fundamentals of A/C diagnosis haven’t changed—your operating environment has.

- Mixed refrigerants are common. Dealership bays service both R‑134a and R‑1234yf vehicles every week.

- EV/hybrid A/C work is high-stakes, and inconsistent diagnostics can lead to repeated inspections or unnecessary parts movement.

- Every extra evac/recharge cycle wastes time and refrigerant (especially with R‑1234yf).

A visible, repeatable method helps teams move from “suspected leak” to “confirmed leak point” without adding complexity.

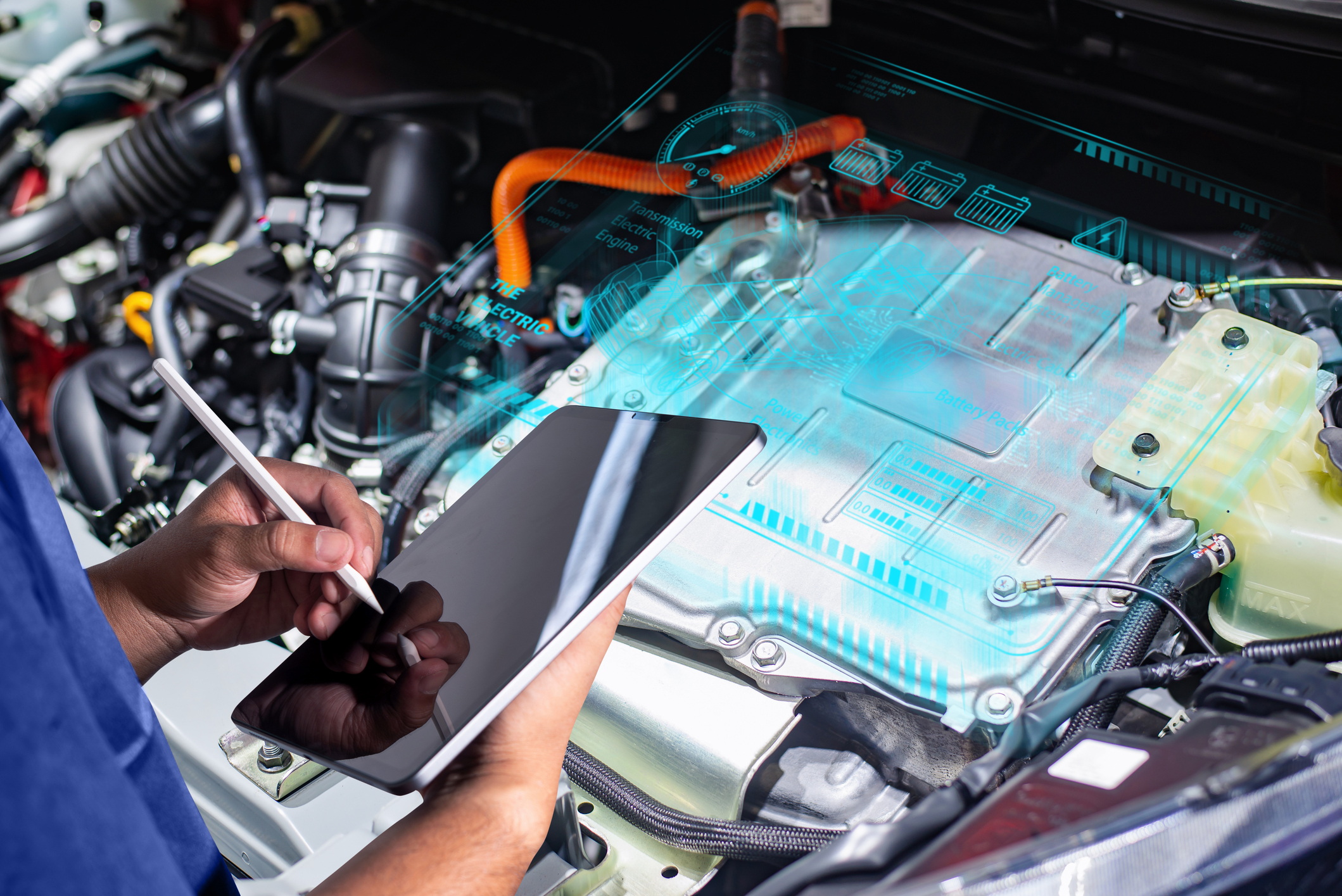

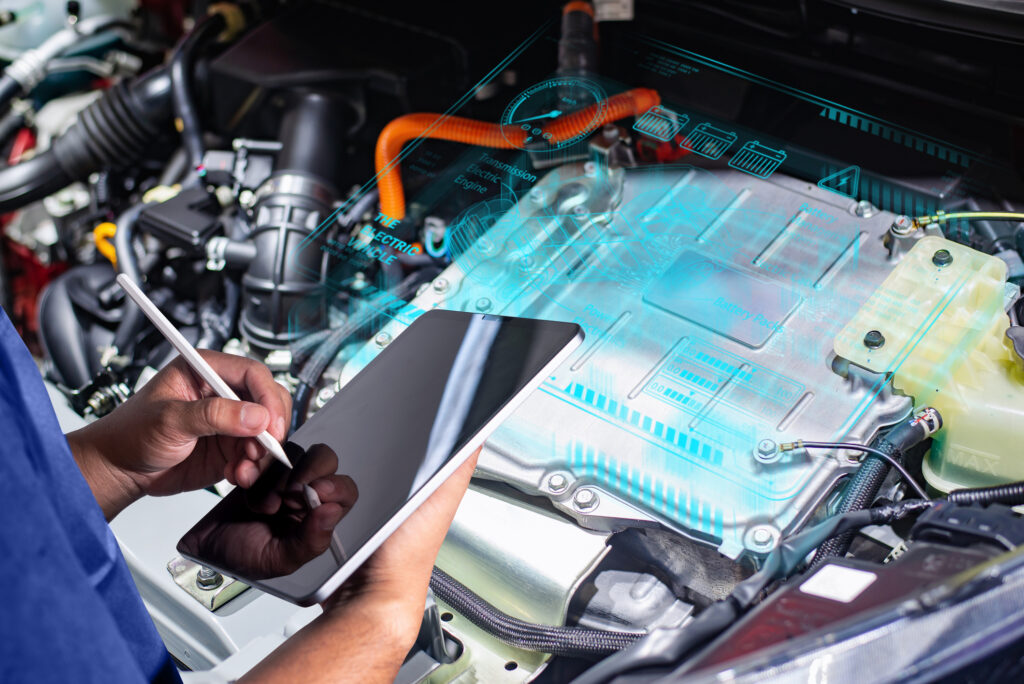

What a compatibility-first UV dye approach means for EV/Hybrid systems

“Compatibility-first” means choosing leak detection products engineered for modern EV and hybrid A/C system designs and built for the refrigerants you actually service.

Tracerline’s POE-based EV/Hybrid A/C products are described as engineered with high dielectric properties to protect EV system components (including electrically driven compressors) and compatible with R‑134a and R‑1234yf systems.

That compatibility supports standard work: one method your team can run consistently across bays and shifts.

Step-by-step dealership workflow: add dye, circulate, inspect under UV

A UV dye process is easiest to roll out when the tools are consistent. One “ready-to-deploy” option is the Tracerline TPOPUV20EV complete UV leak detection kit. It includes TRACER® UV dye specially formulated for use with high-voltage electric compressors and sensitive hybrid A/C components. The dye is described as circulating cleanly without affecting system performance and glowing bright under a leak detection flashlight—helping technicians find leaks fast and prevent refrigerant loss.

What’s in the TPOPUV20EV kit

- TP9815EV‑P3: (3) 0.25 oz (7 ml) single-dose EV A/C dye cartridges (services up to 3 vehicles)

- TPOPUV OPTI‑PRO™ UV cordless, violet light LED leak detection light

- TP9845 EZ‑Ject™ dye injector assembly

- TP9813 brass, swivel-type R‑134a coupler for EV/Hybrid (with check valve and purge fitting)

- TP28 brass, swivel-type R‑1234yf coupler for Hybrid/EV (with check valve and purge fitting)

- TP19 GLO‑AWAY™ Plus fluorescent dye cleaner (2 oz / 60 ml spray bottle)

- TP9940 fluorescence-enhancing glasses

The workflow standardized across bays

Always follow OEM service information and your dealership’s safety procedures for refrigerant handling and EV/high-voltage systems. Then run the same sequence every time:

1. Confirm the concern and capture baseline notes

Verify the complaint and document conditions so the job can be handed off cleanly.

2. Inject dye using the EZ‑Ject™ injector + the correct coupler

Select the appropriate coupler (R‑134a or R‑1234yf) and use the EZ‑Ject™ dye injector assembly to introduce one single-dose cartridge. TP9815EV‑P3 cartridges are positioned for single-billable dosing and described as a high-quality, concentrated dye that fluoresces easily and does not alter the properties of the compressor oil.

3. Circulate the dye

Run the A/C system long enough for dye to travel through the circuit with the refrigerant/oil.

4. Inspect under UV

Use the UV cordless violet LED light and fluorescence-enhancing glasses to scan likely leak areas. If residue is heavy, clean and re-check under UV.

5. Repair and verify

After correcting the leak source, re-check under UV to confirm the leak signal is resolved.

Speed comes from a consistent scan routine.

Start with a quick first-pass sweep in the same order each time:

- Service ports, caps, and valve cores

- Line fittings and O‑ring joints

- Hose crimps and flex sections

- Condenser face/end tanks and connection points

- Compressor body/fittings and nearby joints

- Receiver/drier or accumulator connections (where applicable)

- Evaporator-area indicators (for example, evidence near the drain outlet)

Tip: scan clean and scan systematically—wipe grime when needed, then follow your pattern so you don’t miss steps.

In dealership service, diagnosis has to translate into a clear recommendation and a record that holds up later. UV dye helps because it creates a simple proof point: the leak location is confirmed, not assumed.

Keep RO notes consistent:

- Concern verified

- Dye added and circulated

- Leak location confirmed under UV (component/connection)

- Repair performed

- Verification under UV completed

When your process allows, a quick UV photo can support the technician-to-advisor handoff and reduce back-and-forth.

Dealership teams don’t need more steps—they need fewer unknowns. A compatibility-first UV dye workflow makes EV/Hybrid A/C leaks visible, supports repeatable diagnosis across bays, and helps techs and advisors move faster with clearer documentation.

Using visual confirmation to support advisor communication and RO notes

In a dealership environment, diagnosis has to translate into a clear recommendation and a record that holds up later. UV dye helps because it creates an explainable proof point an advisor can stand behind: “we confirmed the leak location.” It supports continuity if the job changes hands. And when your process allows, a quick photo under UV can provide a simple record tied to the repair decision.

Keep RO documentation tight and repeatable. A clean framework usually captures: the concern verified; dye added and circulated; leak location identified under UV (specific component/connection); the repair performed; and verification under UV after repair. That structure keeps the narrative simple and defensible: complaint → confirmation → correction → verification.

Bringing it all together

Dealership teams don’t need more steps—they need fewer unknowns. A compatibility-first UV dye workflow makes EV/Hybrid A/C leaks visible, keeps the process consistent across technicians, and supports clearer handoffs to advisors. That’s how you reduce rechecks, limit unnecessary part swaps, and shorten the time between symptom and solution. Check out our entire video library on YouTube to learn about our other exciting products. Contact us today to learn more about EV/Hybrid UV Dye for efficient A/C diagnostics.