INSTRUCTIONS

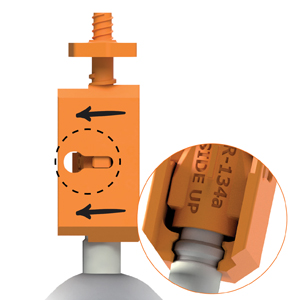

Step 1

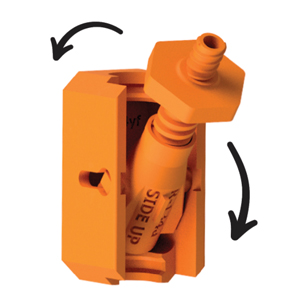

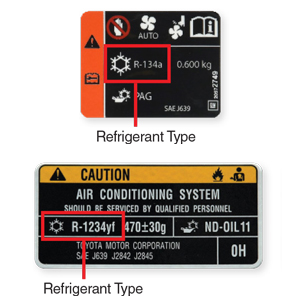

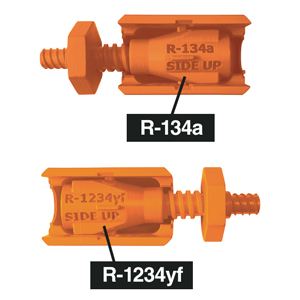

Identify refrigerant system type (see owner’s manual) and prepare adapter. Holding the dual-adapter in hand, pivot the inner body to either R-134a or R-1234yf SIDE UP, respective to your system type.

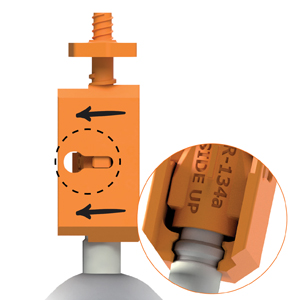

Step 2

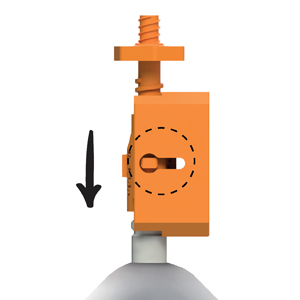

Locate the low-side A/C service port. Push the adapter onto low-side service port.

NOTE: Make sure outer slide is pushed backward away from inner body (see dotted line).

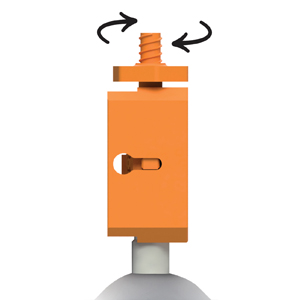

Step 3

Push outer slide forward to lock adapter into place.

NOTE: Connection should feel tight, not loose. If a loose connection is made, adapter will not work properly. Repeat Step 2 until tight connection is made.

Step 3

Push outer slide forward to lock adapter into place.

NOTE: Connection should feel tight, not loose. If a loose connection is made, adapter will not work properly. Repeat step 2 until tight connection is made.

Step 4

Turn knob clockwise to engage service valve and secure a connection.

NOTE: Make sure to turn the knob all the way down – resistance is normal.

Step 5

Before injecting sealant, start the engine and adjust the A/C to the maximum cooling level.

Caution: Beware of moving engine parts.

Step 5

Before injecting sealant, start the engine and adjust the A/C to the maximum cooling level.

Caution: Beware of moving engine parts.

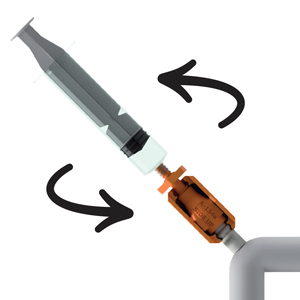

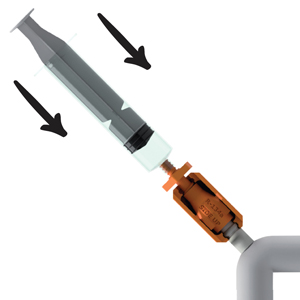

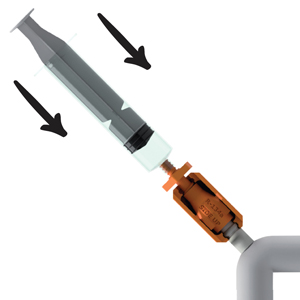

Step 6

Remove syringe cap and screw tip into adapter’s receiving port.

Step 7

Push firmly down on syringe plunger and inject sealant into your system. Once plunger is empty, disconnect and dispose.

Step 7

Push firmly down on syringe plunger and inject sealant into your system. Once plunger is empty, disconnect and dispose.

NOTE: The LF200CS comes with an optional flexible extension hose.

Before connecting the syringe to the dual adapter (as depicted in Step 6), first attach the extension hose to the syringe. Next, press down on the syringe plunger to advance a small amount of sealant through the empty hose (a small amount of sealant should appear at the end of the extension hose). This step will purge the hose of air and is necessary for injection. Lastly, connect the syringe with its purged extension hose to the dual adapter and inject sealant into the system (Step 7).

DUAL ADAPTER

ADAPT

Identify refrigerant system type (R-1234yf or R-134a) and prepare adapter.

CONNECT

Connect the adapter to the low-side service port.

INJECT

Install the syringe and inject sealant.

DETAILS

• Permanently seals pinhole leaks in accumulators/ receivers, evaporators/ condensers, O-rings, and hoses.

• LeakFinder A/C Leak Sealant is a proprietary blend of polymer-free, nonflammable, and non-carcinogenic additives that seals pinhole leaks caused from pitting, corrosion, loosened fittings or abrasion.

• When LeakFinder A/C Leak Sealant is added to a leaking system, the sealant coagulates at a leak site where there is a pressure or temperature differential. LeakFinder A/C Leak Sealant forms a pliable web-like seal.

• Non-polymer, non-hazardous, oil-soluble formula.

• Compatible with hybrid/EV. Safe to use in electrically driven A/C compressors.

IMPORTANT

• The A/C system must contain enough refrigerant to operate the compressor and circulate the LeakFinder A/C Leak Sealant in order to seal leaks.

• Wear protective glasses or goggles while working on any A/C system.

• For vehicle A/C systems, use the entire LeakFinder A/C Leak Sealant prefilled syringe to service single vehicle.

• Adapter is intended for single-use.

• Prior to injecting LeakFinder A/C Leak Sealant into an A/C system, inspect the service port(s) and valve cores for damage.

• A/C Machine and Equipment Safe – LeakFinder sealant is non-polymerizing and safe to use with refrigerant recovery/recycle/recharge (RRR) equipment. The formula is oil-soluble, non-hardening, and not activated by moisture.

Product Troubleshooting

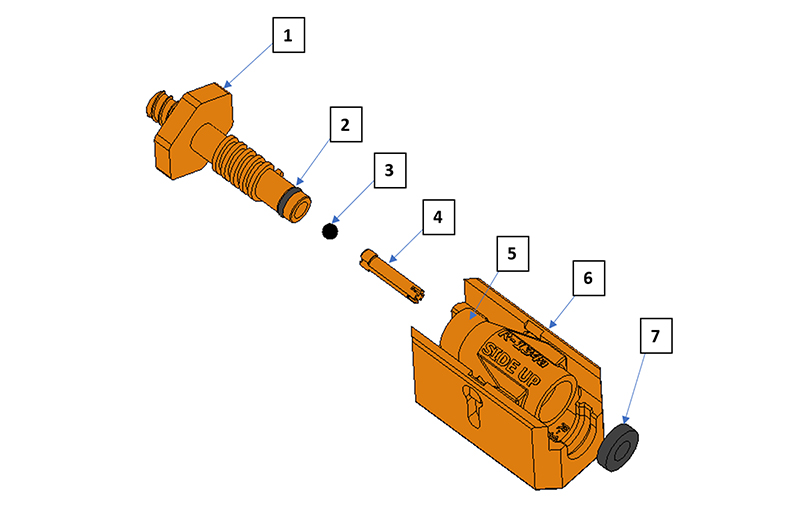

If the LF200CS adapter is accidentally disassembled, please reference the diagram below and follow the instructions. A product animation is also available and provides a visual reference for reassembly.

LF100CS ADAPTER | ||

ITEM | QTY | DESCRIPTION |

1 | 1 | KNOB |

2 | 1 | O-RING |

3 | 1 | BALL |

4 | 1 | PIN |

5 | 1 | INNER BODY |

6 | 1 | OUTER SLIDE |

7 | 1 | GASKET |

If the gasket (Item 7) is disconnected, firmly reseat the gasket in the outer slide (6). If the knob (1) is disconnected from the adapter, first ensure the ball (3) is inserted in the knob’s lower opening and then continue to place the pin (4) in the knob’s opening as well. Next, turn the knob clockwise into the top of the outer slide (6). The knob and the outer slide are now secured, and the LF200CS adapter is ready for use.

WARNING: Keep out of reach of children. Wash thoroughly after handling. Wipe all spills to avoid stains. Store in a cool place away from sunlight. Store in climate controlled, dry area. Store 40-100˚F (4.4-37.7˚C). Dispose of in accordance with all local, state and federal regulations.