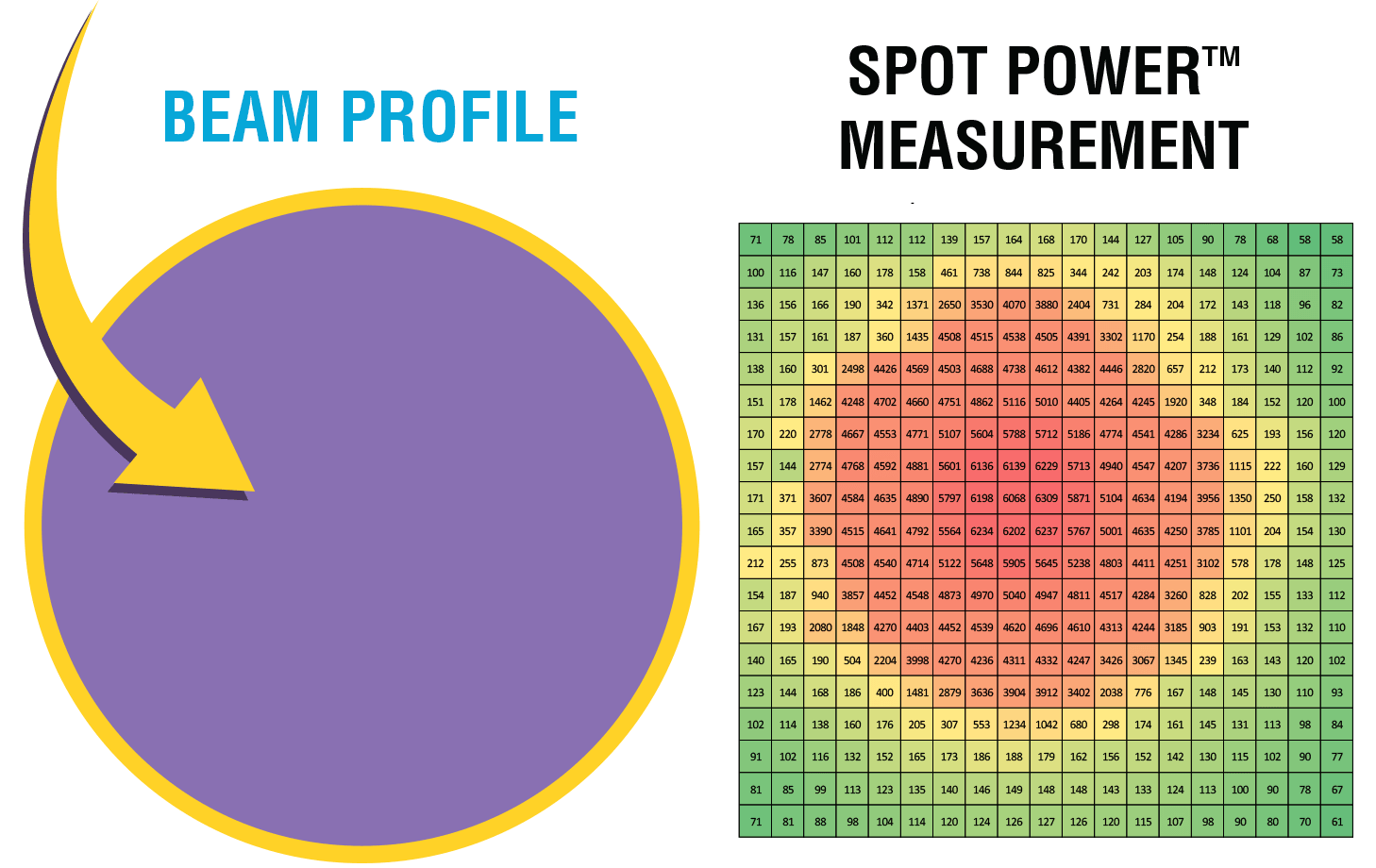

As the inventors of ultraviolet fluorescent technology, Tracer Products’ mission is to educate the automotive market on the true measure of lamp performance. For this purpose, we developed the Spot Power™ metric to gauge lamp performance. Spot Power™ takes extremely accurate measurements of a lamp’s beam profile.

WHAT IS SPOT POWER™?

Spot Power™ measures the effective coverage area of a lamp’s beam. For years, peak beam intensity was used to measure lamp performance. BUT THIS METRIC IS MISLEADING! A lamp’s beam profile should have powerful and evenly distributed coverage. Otherwise, multiple and hidden leak sites could be missed. To capture this data, beam intensity measurements were taken every ½ inch across the beam profile at a distance of 15 inches.

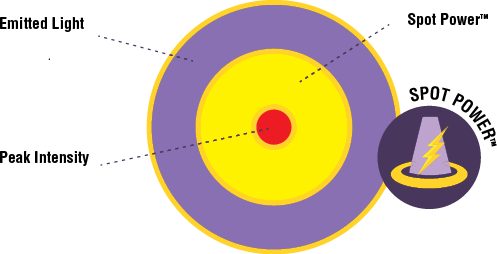

Emitted Light: This is the extent of the beam profile. Typically, the light intensity weakens here and becomes ineffective.

Peak Intensity: Usually in the center of the beam, this is the “hot spot” where the beam is strongest.

Spot Power: is the area within the beam profile that is optimal for activating fluorescent dye.

This methodology of testing is used in industries that require precise measurements for inspecting critical parts – such as in aerospace, mining, heavy-duty automotive, infrastructure, and other industries. It requires a great deal of technical expertise, specialized testing equipment, and engineering.

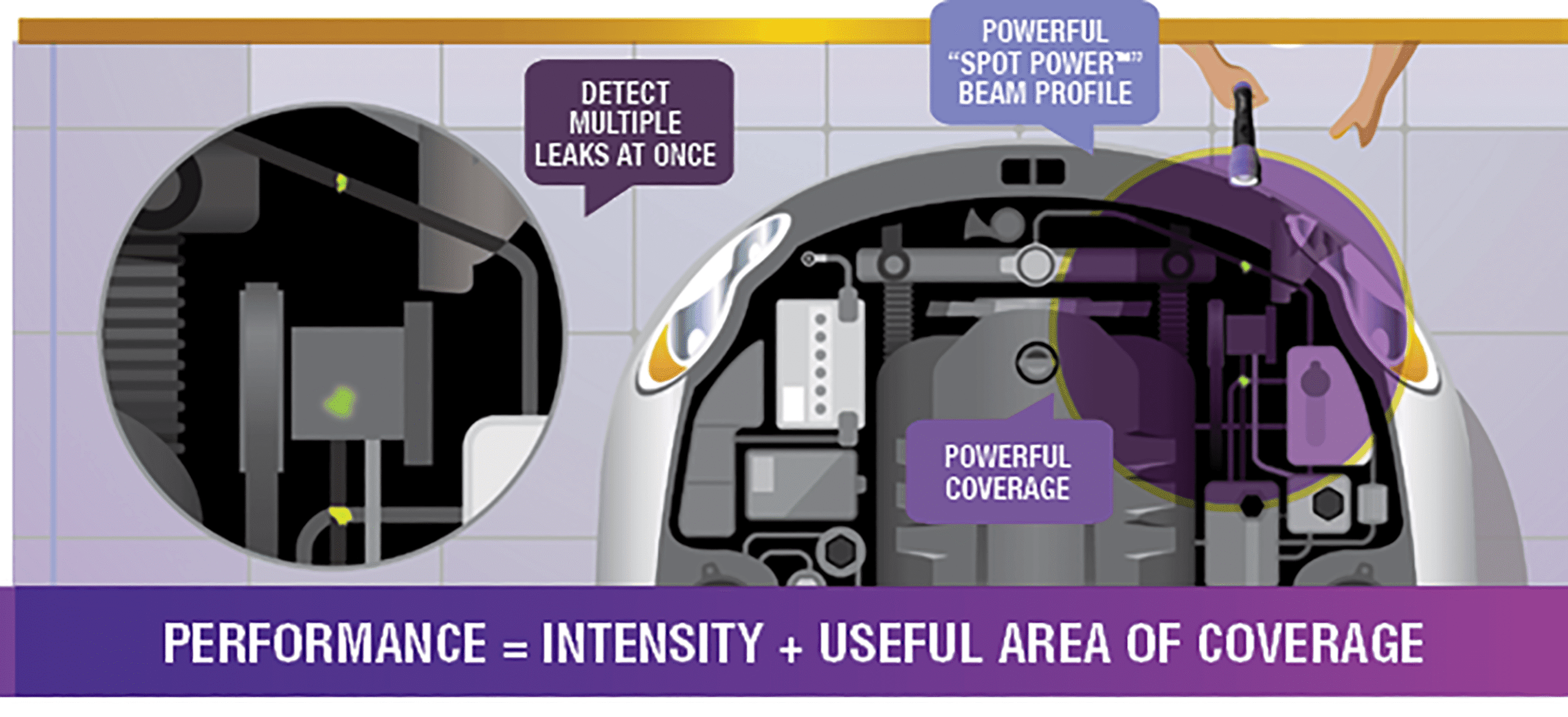

Essentially, Spot Power™ takes a snapshot of lamp intensity, coverage, and effectiveness. It is critical that a leak detection lamp has a powerful and evenly distributed beam profile. Otherwise, leak sites could be missed during the inspection – leading to callbacks and system failure.

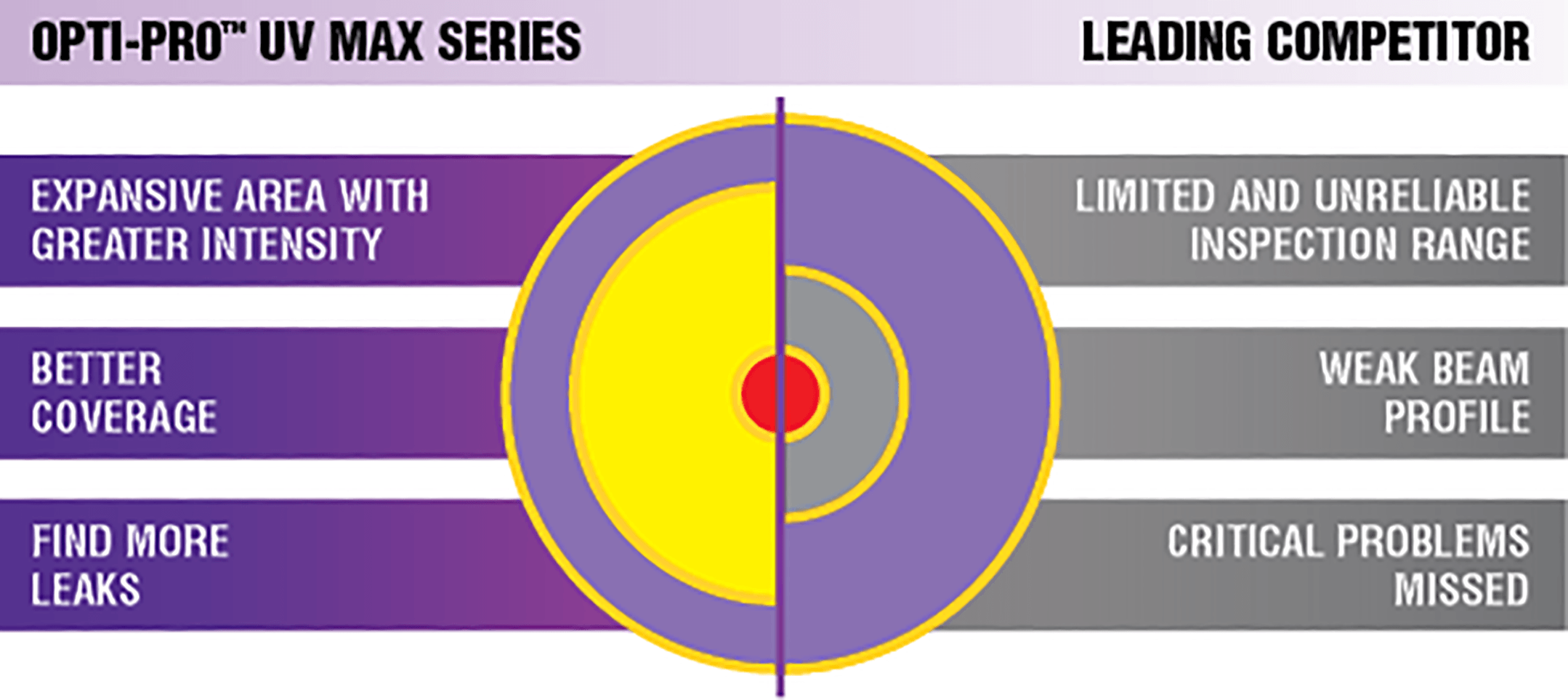

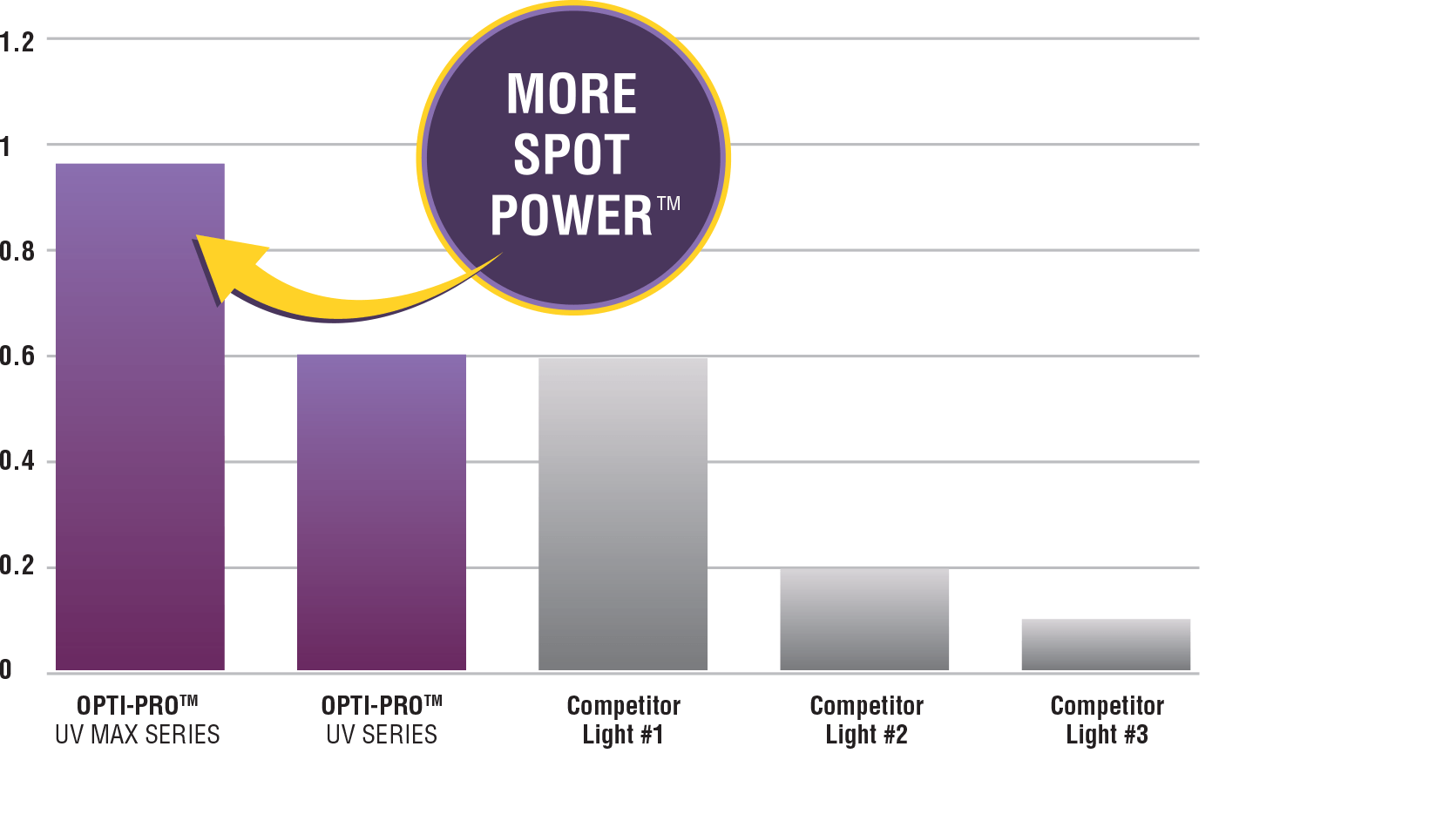

The new OPTI-PRO™ UV MAX outperforms the competition significantly – finding more leaks in a single scan. Competitor lamps have weak, uneven coverage and their Spot Power™ ratings are ineffective. This lower performance can leadto false-positive repairs

and callbacks.