Preventative Maintenance Saves Time

Preventative maintenance can save your company’s vehicle fleet hundreds – even thousands – of hours per year. Vehicle downtime hurts productivity and is six times costlier than an emergency, corrective maintenance. Preventative maintenance reduces the amount of time it takes to keep a vehicle in optimal working condition and can detect problems before they become much worse.

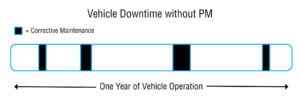

The diagram below depicts the amount of vehicle downtime over the course of a year. The fleet manager of this organization has no preventative maintenance plan in place. The manager relies solely on corrective maintenance to maintain the fleet.

Within this timeframe, four breakdowns occurred totaling 417.6 working hours of downtime for corrective repair.

The vehicle up-time totaled around 80.8% for the year.

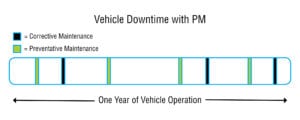

The next diagram depicts vehicle downtime AFTER a preventative maintenance plan has been implemented.

In the diagram above, the intervals of downtime are much smaller and more frequent.

Over the course of a year, vehicle up-time was recorded at 95%.

The vehicle was taken out of operation for short periods of time, inspected, and serviced appropriately.

During these scheduled events, potential problems can be identified early on and preemptive repairs can be made.

These small repairs ultimately saved the company more hours because the vehicles didn’t suffer a critical failure that would have otherwise taken much longer to repair.

When a vehicle breaks down for unknown causes, it takes much longer to diagnosis the problem. Having an up-to-date record of maintenance for every vehicle decreases the time it takes to diagnose a problem.

Remember, downtime is largely based on parts availability and delivery. It takes a lot of time and effort to coordinate the logistics of the repair. For fleet managers, time is the ultimate currency.

Summary of Results:

Without preventative maintenance: 417.6 hours of downtime.

With a preventative maintenance plan: 104.4 hours of downtime.

Total time saved by utilizing a preventative maintenance plan: 313.2 hours of time saved throughout the year.

The up-time for the company (with a PM plan in place) was found to be at 95.1%.

Adopting a preventative maintenance plan ended up saving about 313.2 hours in lost downtime due to breakdowns or missing parts.

Cycles of Maintenance

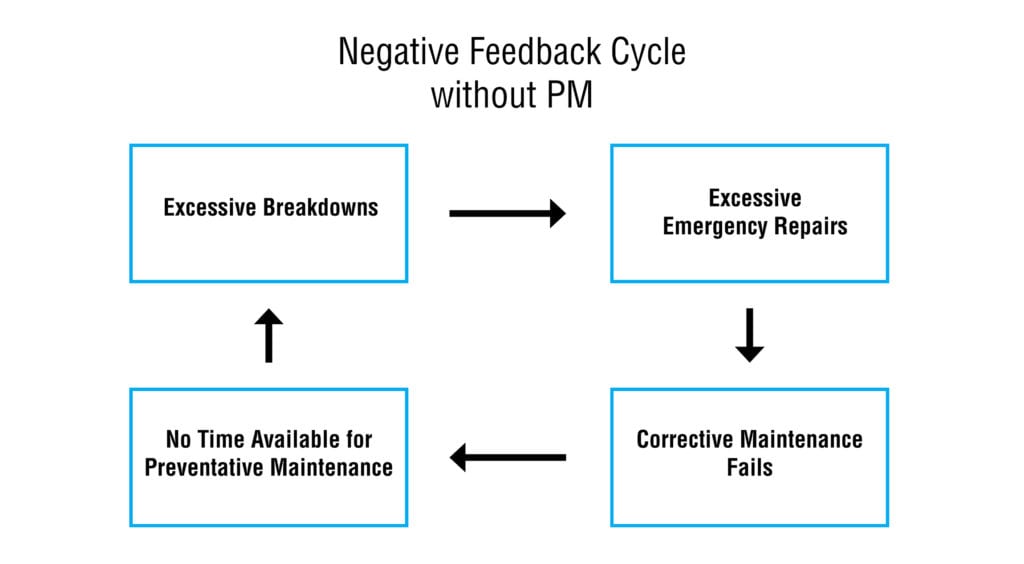

Cycles of maintenance can either be negative or positive.

A negative cycle of maintenance involves emergency repairs. These emergency repairs lead eventually to more emergency repairs.

How does this happen?

Because emergency repairs are time-consuming and costly, these repairs naturally steal time away from the maintenance of your existing equipment.

Reactive maintenance leads to more work.

Once you are in this negative cycle of maintenance, it’s very difficult to escape.

A company can quickly become comfortable with jumping from emergency to emergency.

The corporate culture becomes reactive – always needing to adapt and catch the next emergency.

Company culture can decide if a business thrives or fades.

If your organization is small, it may be too difficult to step back, stop reacting to the situation, and take a measured look at how your business is operating.

In cases such as these, it’s very difficult to analyze and manage company resources.

Excessive breakdowns lead to emergency overtime hours and further deplete company resources. This prevents your company from breaking the negative cycle.

Stop the cycle of constant losses and wasted effort. Begin a new, prosperous cycle.

Because all company resources are busy making emergency corrective repairs, equipment that would otherwise be operational with regular maintenance now has the potential to breakdown and become unusable.

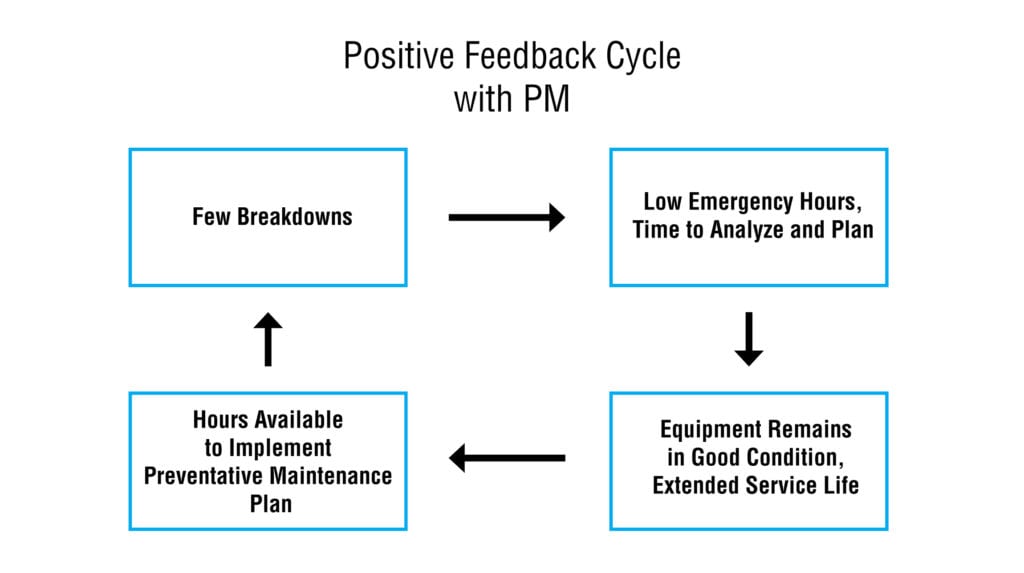

The positive cycle of maintenance is self-perpetuating.

Although breakdowns are inevitable and equipment cannot last forever, company resources are more appropriately managed in a positive cycle of maintenance.

A PM plan helps your business make the right decisions and frees up resources.

A positive cycle of maintenance experiences few emergency breakdowns. This means there are less emergency hours and there are time and money available to invest in other areas of business development.

The reason why many businesses don’t adopt effective PM plans is simple.

Business owners see preventative maintenance as an expense. But they should really see it as an investment.

In competitive markets, having optimized operations can help your company reduce costs and ultimately lower your prices for the consumer.

Similarly, preventative maintenance goes hand-in-hand with quality control and excellence in service.

Preventative maintenance means your standardizing your operations.

Great PM plans only work if all gears are moving in the same direction.

Quality and consistency naturally improve with a PM plan. It’s a byproduct and the net positive of having a detailed plan.

Your customers will thank you for your top-tier service and consistency.

TP-8692 UV多色液态染料包。

如果车辆在两次检查之间持续流失运行液,这就说明车辆漏油了,意味着问题严重。

泄漏可大可小。如果泄漏量很大,车辆系统就会关闭,完全停止工作。

But smaller leaks can erode at system integrity over a longer period of time, inflicting damage slowly and perhaps unnoticed.

In cases such as these, the UV Multi-Colored Fluid Dye Kit is the perfect preventative maintenance solution.

在一次扫描中,彩色编码荧光染料可以快速有效地检测到多个系统的泄漏。

即使是最小和最困难的泄漏也能被检测出来。

在2016年的一份行业报告中发现,预防性维护工具,如紫外线荧光检漏,可以阻止1/4的车辆系统故障--每年为车主节省数百甚至数千美元。

通过一套颜色编码的检漏染料,一名技术人员可以诊断多个车辆系统的泄漏。

The kit includes three color-coded dyes for petroleum and synthetic-based fluids: white dye, yellow dye, and blue dye (red dye is sold separately). These multi-color dyes allow a technician to check for transmission, brake, oil, fuel, power steering, and other fluid-based leaks.

The kit also includes a specially designed green fluorescent dye for conventional coolant.

Tracerline的UV染料浓度高,使用安全,不会影响车辆系统的化学特性,也不会改变油液的工作方式。

这些特种染料可以安全地保留在液体系统中。

这意味着一旦修复,染料可以作为预防性维护计划的一部分。

每次客户再来保养车辆时,技术人员只需用紫外线检漏灯扫描车辆系统即可。

If there are new leaks in the system, the fluorescent dye will glow brilliantly and indicate the exact location of all new leaks, across all fluid-based vehicle systems. Tracerline’s UV Multi-Colored Fluid Dye Kit has been featured on the cover of Professional Tool and Equipment Magazine’s December 2017 Issue.

Tracerline’s UV Multi-Colored Fluid Dye Kit has been featured on the cover of Professional Tool and Equipment Magazine’s December 2017 Issue.

它是第一个也是唯一一个完全可定制的、彩色编码的泄漏检测套件,适用于所有基于流体的车辆系统。